Description

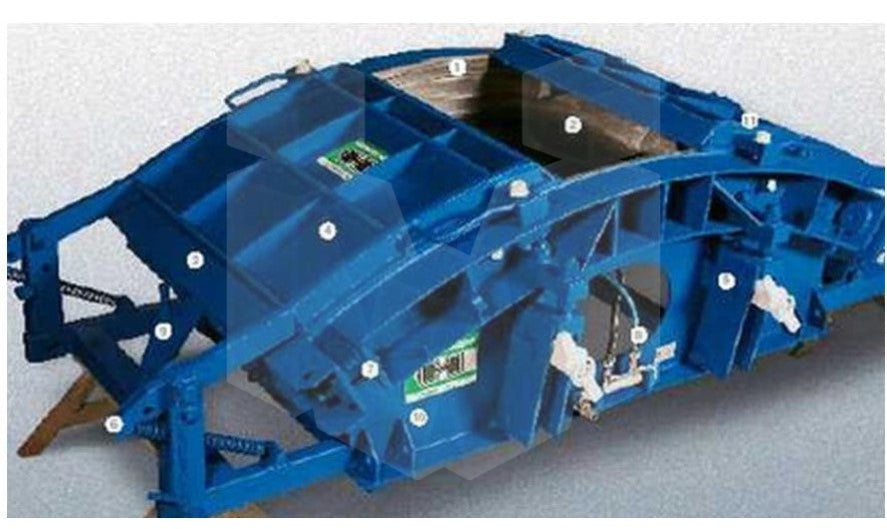

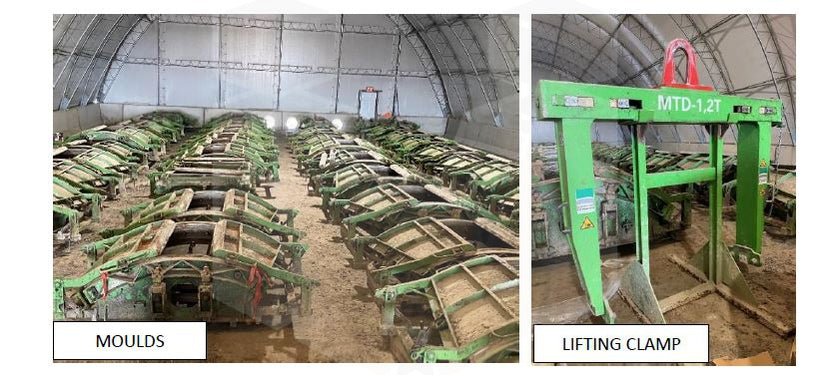

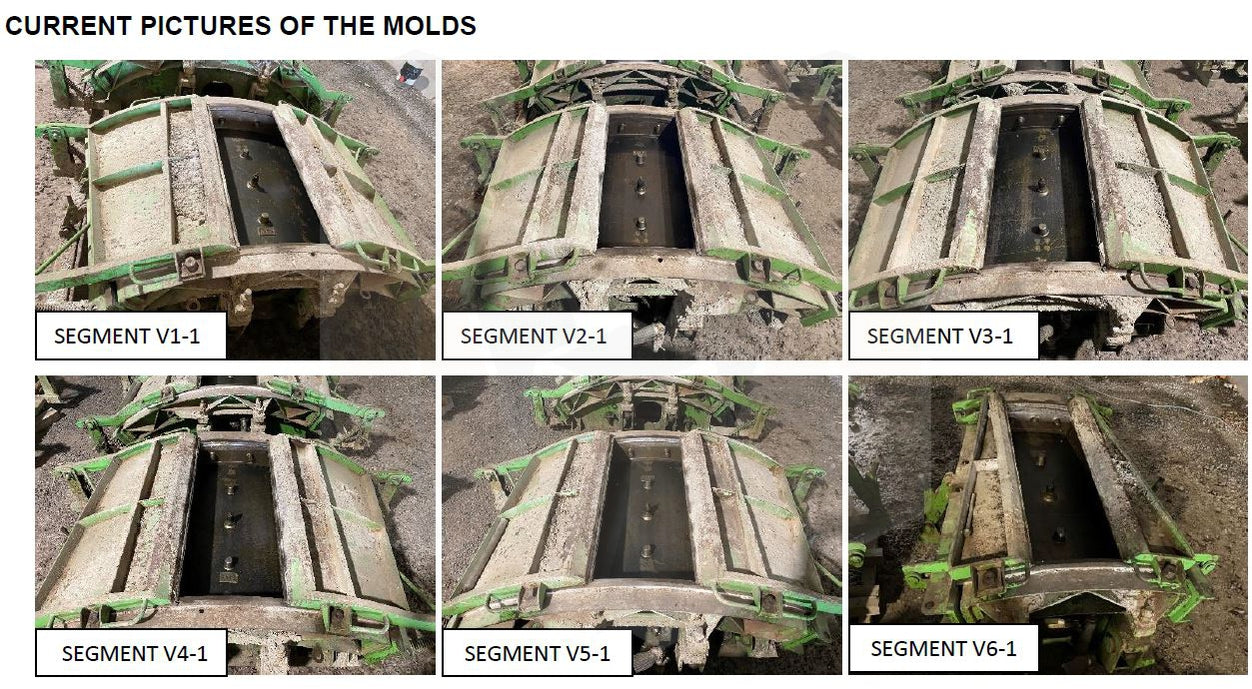

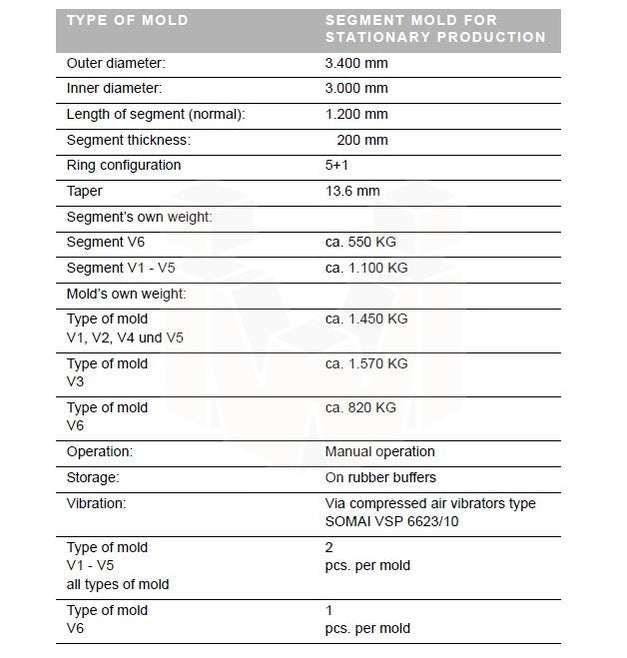

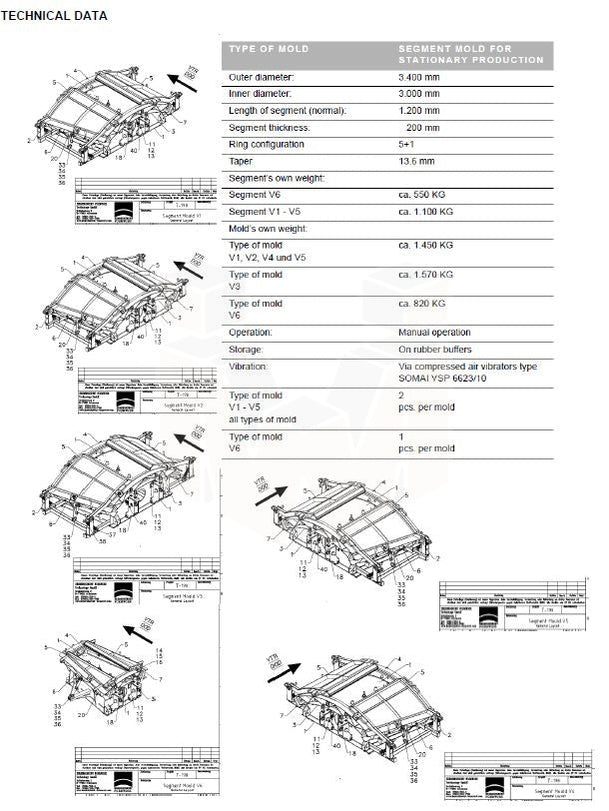

Herrenknecht tunnel molds (2017): The mold is consisting of base frame (10) with mold bottom on top (2), two front shutters (3), two side shutters (1) and one-piece or split mold covers (4). Beneath mold bottom, vibrators are fixed and intended for compacting filled-in concrete. Mold bottom forms the shape of internal tunnel tube, front shutters form concrete contact area to proximate segments of same ring and side shutters form concrete contact area of segments to proximate ring. There are two types of side shutters: side shutter DOD and side shutter counter DOD, whereas DOD means "direction of drive” and counter DOD describes the side facing to starting point of tunnel. From this follows that next (new) ring of tunnel tube will always be connected with existing tube with its counter DOD-side. On inner side of mold there are, depending on intended use, holders for different inserts. Inserts will be mounted onto holders in the mold prior to concreting. After demolding, inserts are intended to fix and connect segments to the tube. On mold bottom, so called erector center cone is installed. Erector is TBM’s handling equipment for segments. Erector center cone is used as a position reference point for TBM, because segments are handled by vacuum devices. The erector is located at the back end of the shield segments but still inside the tailskin. It serves the mounting of the ferro-concrete segments and finally the protection of the operating personnel and the stabilization of the unsecured tunnel wall. Our segment molds are equipped with pneumatic or electrical vibrators. Advantage of electrical vibrators is the possibility to control rotational frequency via frequency converter very exactly. As a result of this, compacting process can be better reproduced. DETAILS: No. of Segments : 6 (V1, V2, V3, V4, V5, V6); Total # of Molds : 8 SETS (Total of 48 Units); Lifting/Turning Clamp : 2 Units